|

|

|

|

|

|

|

|

SPLIT SYSTEM CHARACTERS:

1. Perfect design

Split solar heater are designed as flat collectors which is

available to be integrated into the roof to become the perfect

designation.

2. Pressure hot water

The whole system adopt the pressure endured system, which can

provide more strong hot water for the comfortable bathing.

3.Working stability

For the solar heater collectors, it use the heat pipe which

conducting the heat energy. Even if one glass tube broken, the

whole system can work steadily to provide the hot water.

4. computerized control

The control system is necessary for the split system working.

All the automatic function can be controlled by the control

system such as the water in, water out, water temperature show,

high pressure release, automatic circulation, water temperature

control and so on. This system realized the realistic automatization.

The computerized control avoid the manual operation.

5. Diversification of installation

For the installation ,there is more choice, which can be fitted

on the balcony,on roof,on floor or other choices. The installation

avoid the traditional roof installation for the thermal model.

6. Separate type installation.

The heat pipe solar collectors are separated with the tank.

The heat pipe collectors are on the roves and the pressure tank

is in the house. The connection pipe is short ,which can provide

the hot water quickly.

7. available work with the back up power

The split solar system can work with the back up power such

as the gas, electric heater together,which realize the hot water

supply in the cloudy days.

8. Sufficient pressure hot water For the system are pressure

endured, more bath clock can get the strong hot water.

9.Easy installation.

The system are simple installation.

THE COMPOSITION OF THE SYSTEM£º

The heat pipe Vacuum tube collectors

The heat pipe vacuum tube collectors consisted of the Manifold,

heat pipes, aluminium wings, all glass high efficiency vacuum

tubes, outer casing and support frame. Which can pressure endured

operation and collect the heat energy and transfer the heat

energy.

Single coil pressure tank or Dual coil pressure tank.

The pressure tank consisted of the 1.2mm stainless steel inner

tank, insulation ,outer tank and single coil or dual coil for

the heat exchangerring.

Control system

The control system consisted of the computerized controller,

pump, expansion tank and other part for the automatic operation.

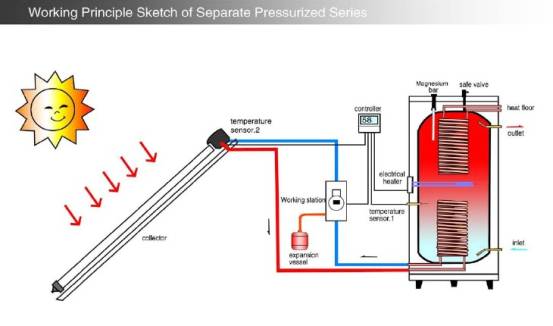

WORKING THEORY£º

1. The solar collector collect the sun energy by the vacuum

tube absorption and heat pipe conduction.

2. By he evaporation and liquidation process, the heat energy

are conducted to the liquid passing the manifold , which take

the heat energy away.

3.The control system control the heat energy conduction in the

closed system, which realize the transition from the manifold

to the tank heat exchanger.

4. The heat is transferred from the heat collector to the water

tank by the heat exchanger

5.The circulation process is set in the fixed formula.

6.It¡¯s not necessary for the circulation to work all the time..

7.The back up power such electric heater or gas heater or other

power can work with the solar system too by the special control

system instructed.

8. Coil heat exchanger realize the transition of the heat energy

from the conducting from the conducting liquid to the water

tank water

9. Then we got the tank hot water for the life..

Technical parameter

|

Manifold Casing Material

|

304 Stainless Steel

of Powder Coated Aluminium

|

|

Frame Material

|

Stainless steel

or galvanized steel

|

|

manifold

|

C12200 Copper

|

|

Insulation

|

Polyurethane 55mm

with the mineral wool

|

|

Rubber Seals and Rings

|

silicon rubber

|

|

Optimal installation angle

|

15-85¡ã

|

|

Maximum Operating Pressure

|

6bar-85psi

|

|

Pressure Drop

|

700Pa@3.3L/min

for 20 tube manifold(SRCC)

|

|

Optimal flow rate

|

0.1L/min/tube-0.026G/min/tube

|

|

Performance Data(SPF)

|

Conversion Factor:

ho=0.717

Loss Coefficients:a1=1.52,a2=0.0085

|

|

Manifold Casing Material

|

304 Stainless Steel

of Powder Coated Aluminium

|

|

Frame Material

|

Stainless steel

or galvanized steel

|

|

manifold

|

C12200 Copper

|

|

Insulation

|

Polyurethane 55mm

with the mineral wool

|

|

Vacuum tube

|

RT-MC

|

|

HEAT PIPE

|

0.5¡ª0.8mm

|

|

Manifold thickness

|

1.2mm

|

|

Connection size

|

3/4inch,1inch,

or 1/2 inch screw

|

|

Heat pipe life

|

15 years

|

|

|

|

|

|

|

|